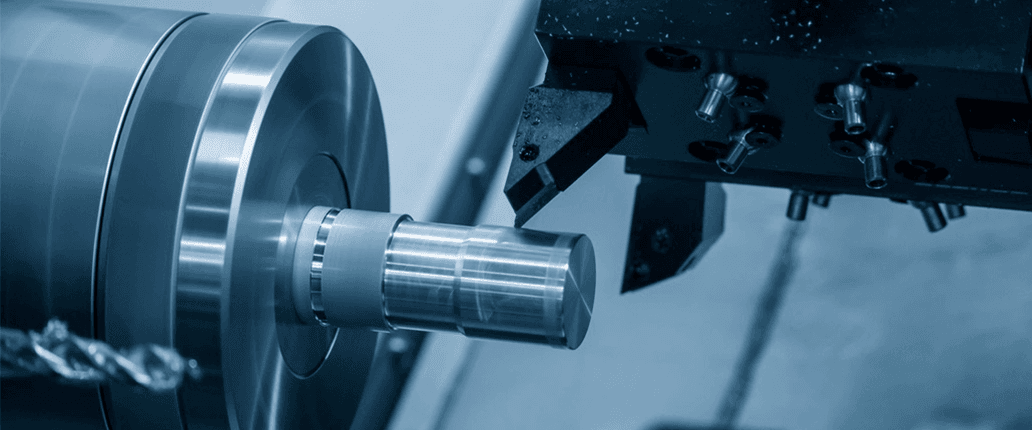

MachineDesign.top High-precision Micro Machining

Whether you’re an independent designer, a small studio, or a large design firm, we’re here to bring your creative visions to life with efficient and reliable manufacturing services. From prototyping to large-scale production,

MachineDesign.top

offers one-stop solutions to turn your ideas into reality.