Selecting V&T Machining for your nickel laser cutting needs is choosing a partner committed to precision, quality, and cutting-edge solutions. Our unwavering dedication to excellence, coupled with advanced techniques, positions us as industry leaders in providing tailored nickel laser cutting solutions. At V&T Machining, we understand the unique properties of nickel and have honed our expertise in laser cutting to deliver results that exceed expectations.

Laser cutting has revolutionized material processing, and when it comes to nickel, a specialized approach is essential. V&T Machining takes pride in employing state-of-the-art tools and techniques to deliver precise nickel laser cutting solutions, customized for diverse industries, including aerospace, electronics, and chemical processing.

V&T Machining Presents a Comprehensive Guide to Laser Cutting Nickel:

| Nickel Alloy Composition | Cutting Tool | Cutting Speed (mm/min) | Laser Power (kW) (Thickness-Dependent) | Focus Lens Material | Focus Lens Life (hours) |

|---|---|---|---|---|---|

| Nickel 200 | CO2 or Fiber Laser | 200-400 | 2-4 (thickness-dependent) | ZnSe or Si | 300-500 |

| Nickel 201 | CO2 or Fiber Laser | 250-450 | 2-4 (thickness-dependent) | ZnSe or Si | 300-500 |

| Inconel 600 | CO2 or Fiber Laser | 150-300 | 3-6 (thickness-dependent) | ZnSe or Si | 300-500 |

| Inconel 625 | CO2 or Fiber Laser | 150-300 | 3-6 (thickness-dependent) | ZnSe or Si | 300-500 |

Challenges in Nickel Laser Cutting:

Nickel poses challenges due to its high melting point and hardness. At V&T Machining, we leverage advanced laser technologies and expertise to overcome these challenges, ensuring precise cuts and superior results. Our approach involves optimizing parameters such as laser power, cutting speed, and assist gases for each type of nickel alloy.

Technical Approach:

V&T Machining approaches intricate nickel laser cutting projects with precision and meticulous care. Our experienced team ensures that temperature control, beam alignment, and gas utilization are finely tuned to meet the specific demands of nickel laser cutting. This expertise allows us to achieve superior edge quality, minimal thermal distortion, and reduced material waste.

Optimizing Nickel Cutting Speeds and Laser Positioning:

Our focus on cut speed and laser positioning is crucial for achieving optimal results with different nickel alloys. Identifying the correct initial piercing point on the sheet maximizes beam efficiency, while adjusting power settings and aligning the sheet grain minimize distortion. The use of high-pressure nitrogen or argon during nickel laser cutting enhances the cutting process and achieves a clean, burr-free edge.

Benefits of Nickel Laser Cutting:

- Corrosion Resistance: Nickel laser cutting at V&T Machining provides corrosion-resistant components for industries such as chemical processing.

- High-Temperature Applications: Our advanced laser cutting techniques cater to the unique properties of nickel alloys, providing components for high-temperature applications in aerospace and industrial settings.

- Precision in Electronics: V&T Machining’s expertise ensures precision in nickel laser cutting for electronic components, meeting the stringent requirements of aerospace and electronics industries.

In choosing V&T Machining for your nickel laser cutting needs, you’re partnering with experts dedicated to overcoming challenges, delivering exceptional precision, and providing tailored solutions for your specific industry requirements. Trust us to elevate your projects and exceed your expectations in the dynamic fields of aerospace, electronics, and chemical processing.

Our Laser cutting Nickel equipment

| Working Area | 1510×3050mm |

| Max Linkage Speed | 140m/min |

| Max Acceleration | 1.5G |

| Positional Accuracy | ±0.03mm |

| Re-positional Accuracy | ±0.02mm |

| Pipe Section Shape | Round/Square Tube/Rectangular |

| Tube Size Range (Dual Pneumatic) | T160:Round:Φ16-Φ155mm Square:□16-□155mm Rectangular:Long Side≤155mm T220: Round:Φ20-Φ220mm Square:□20-□220m Rectangular:Long Side≤220mm |

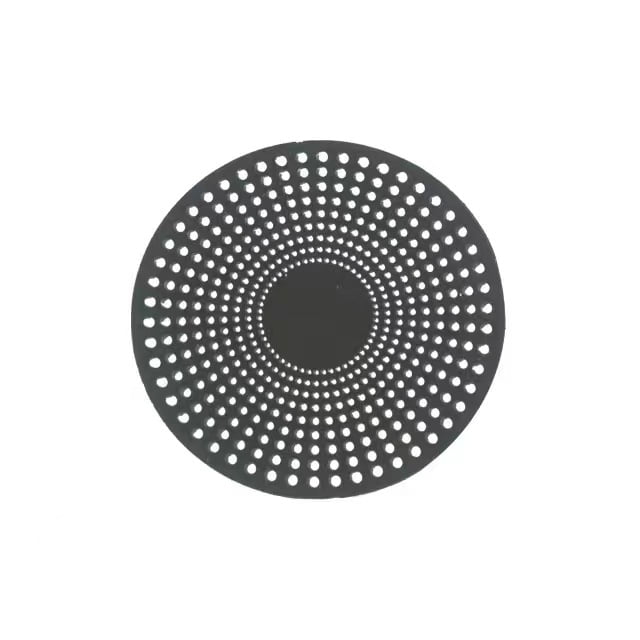

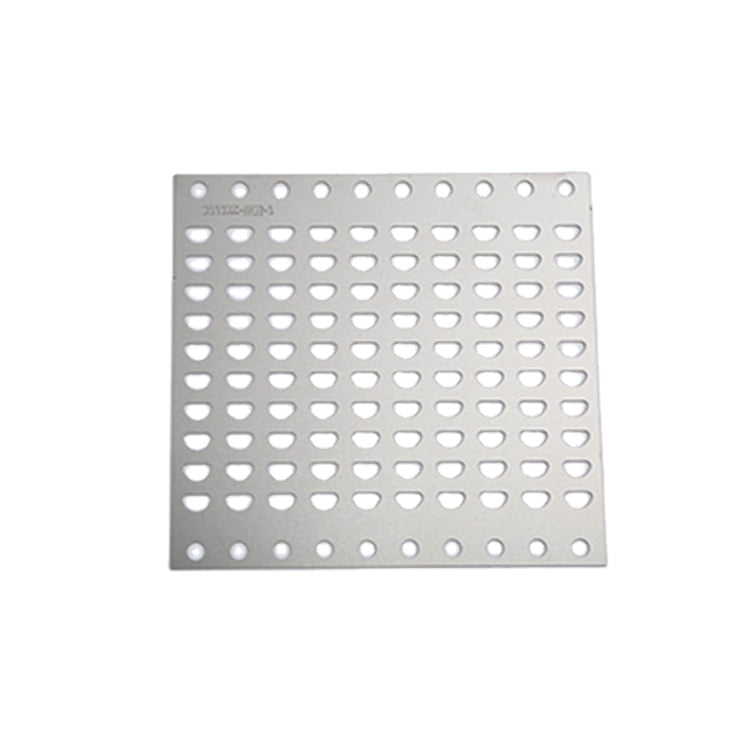

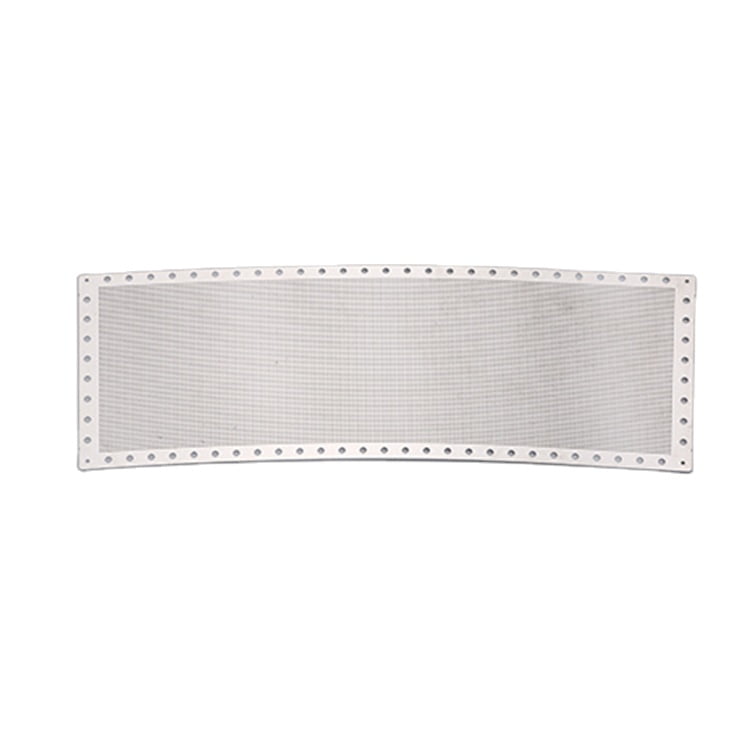

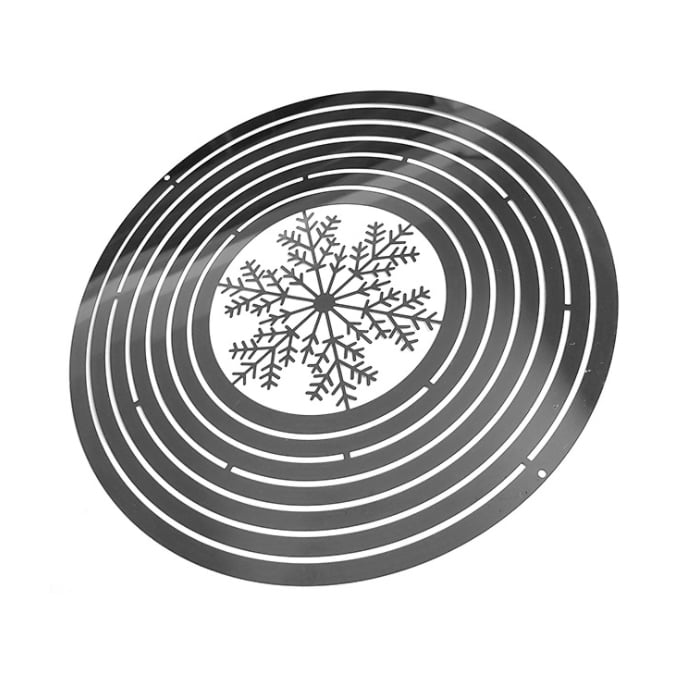

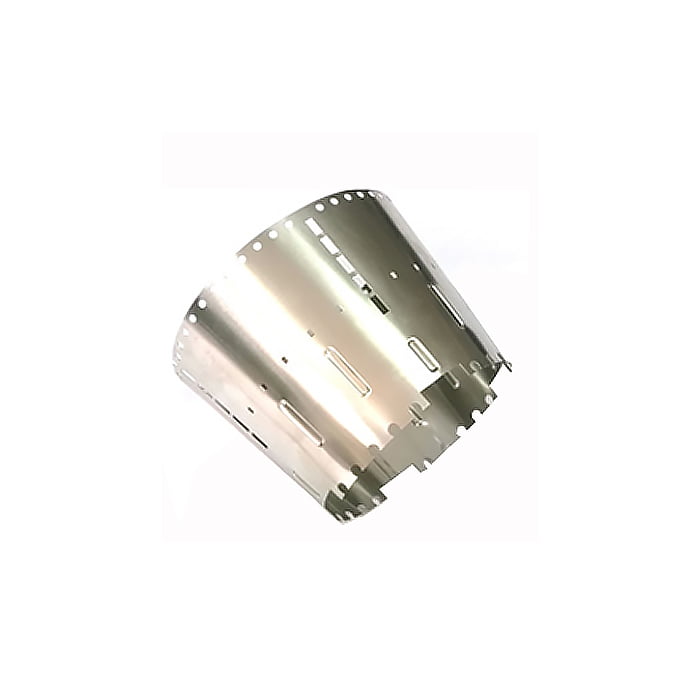

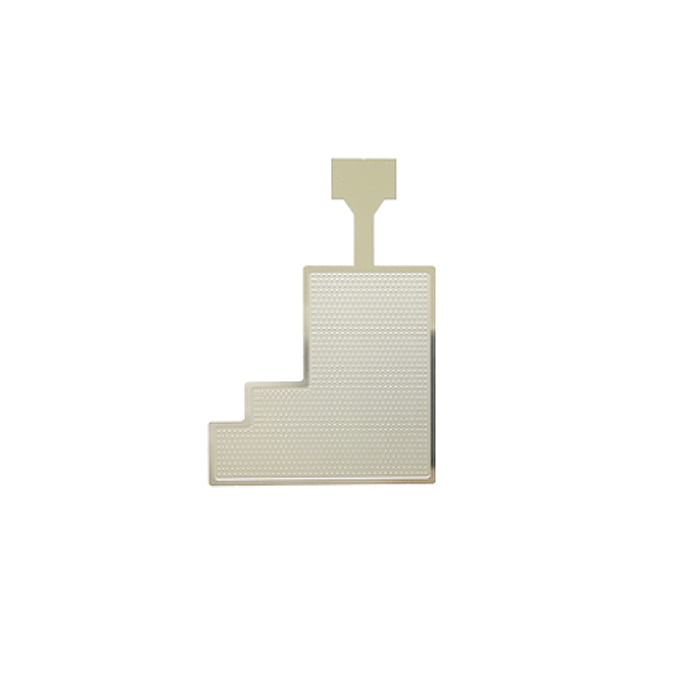

Laser Cutting Samples

FAQ

Do you have your own factory?

Yes, our factory is located in Shenzhen, China. We own a very professional team.

How quickly can I get your response?

Within 24 hours.

Will you do 100% inspection before shipping out the orders?

Yes we do.

Can I have prototypes or samples before placing the order?

Samples are always available.

Are you experienced in different surface treatment?

Yes. We make surface treatment like: anodizing, nickel plating, electrolytic polishing, zinc plating, black oxide,TIN coating...

Are you experienced in different heat treatment?

Yes. We make heat treatment like: Nitriding, Quenching and tempering, Case Hardening, Carburize Hardening, Vacuum heat treatment

Do you make stock for your customers?

Yes in some cases we would make some stock for our customers.

Contact Us

If you need custom metal fabrication, please don’t hesitate to contact us immediately. We will provide you with the appropriate processing price within 2 days of receiving your material.

View V&T service reviews

United Statesthis company is my go to! have used them multiple times great prices V&T is the best to work with!

Robert James

United Statesthis company is my go to! have used them multiple times great prices V&T is the best to work with!

Robert James

Quality yet cheap. Service Staff was very friendly and helpful. Measurements of parts was very accurate for the anodized aluminium, and prices were very competitive

Jerimiah D.

Quality yet cheap. Service Staff was very friendly and helpful. Measurements of parts was very accurate for the anodized aluminium, and prices were very competitive

Jerimiah D.

Good quality of the product, the color matches the photos. The milling machine operator is good. Thanks.

Francy J.

Good quality of the product, the color matches the photos. The milling machine operator is good. Thanks.

Francy J.

If you can deal with V&T you will have a very good experience. Sometimes they can be quite late though, and communication was bad for a while. I have dealt with this company for 3 years now. Mostly satisfied

Marianna B.

If you can deal with V&T you will have a very good experience. Sometimes they can be quite late though, and communication was bad for a while. I have dealt with this company for 3 years now. Mostly satisfied

Marianna B.