Xinxin Precision Sets the Standard for Brass Metal Chemical Etching

With an unwavering focus on precision and craftsmanship, Xinxin Precision has honed its expertise in metal chemical etching, particularly for the elegant and versatile material—Brass. Celebrated for its unique combination of beauty, durability, and adaptability, Brass requires a highly specialized approach to achieve intricate and high-quality results.

View Xinxin Precision Custom Chemical Etching Services

Brass: A Material of Distinction

- Timeless Aesthetic: The warm, golden hue of Brass lends a luxurious touch, making it a favorite for decorative and architectural applications.

- Exceptional Durability: Resistant to corrosion, Brass maintains its integrity in challenging environments, including those with high humidity.

- Unmatched Flexibility: Its malleability allows for the creation of detailed and complex designs, meeting the needs of both artistic and industrial projects.

Precision Etching Techniques for Brass

Xinxin Precision has developed a tailored process for Brass chemical etching, combining advanced techniques with optimal etchant formulations to ensure flawless results. Our approach balances efficiency and precision to create intricate patterns while preserving the material’s distinctive characteristics.

| Etchant Used | Etching Time (min) | Temperature (°C) | Mask Material | Resolution (µm) |

|---|---|---|---|---|

| Ferric Chloride (FeCl3) | 18 | 35 | Photoresist | 3 |

| Nitric Acid & Hydrochloric Acid | 20 | 40 | Silicon Dioxide (SiO2) | 5 |

| Citric Acid & Nitric Acid | 15 | 30 | Silicon Nitride (Si3N4) | 4 |

The Role of Etchants in Brass Etching

Each etchant plays a vital role in achieving the desired precision and pattern detail:

- Ferric Chloride (FeCl3): Known for its precise material removal, ensuring sharp and detailed patterning.

- Nitric Acid & Hydrochloric Acid: Offers a fine balance of selectivity and speed, ideal for maintaining Brass’s integrity.

- Citric Acid & Nitric Acid: Provides high-resolution etching, perfect for intricate designs requiring exceptional detail.

Why Choose Xinxin Precision for Brass Etching?

- Advanced Techniques: We meticulously refine every aspect of the process, from etchant concentration to temperature control, ensuring precision at every step.

- Versatile Applications: Our expertise makes Brass etching suitable for diverse industries, including electronics, musical instruments, and luxury decor.

- Custom Solutions: At Xinxin Precision, we tailor our methods to your unique requirements, delivering results that exceed expectations.

Transform Your Brass Projects with Xinxin Precision

By partnering with Xinxin Precision, you gain access to unmatched expertise in Brass chemical etching. Our commitment to precision and innovation ensures that your designs come to life with impeccable quality and reliability. Whether your project involves delicate artistic details or high-performance industrial components, trust us to deliver solutions that elevate your vision.

About Our chemical etching machine

Precision: The etching precision of our machine is 0.018mm, which allows us to manufacture micro-sized components with high accuracy.

Speed: The etching speed of our machine is determined by the quality and temperature of the etching solution used. Typically, higher temperatures result in faster etching.

Yield: Our machine achieves a high yield rate of 99.9% due to its high precision and controllable etching speed, which greatly improves manufacturing efficiency and reduces costs.

Our equipment comes from the Dragon Etching Chemical Etching Machine.

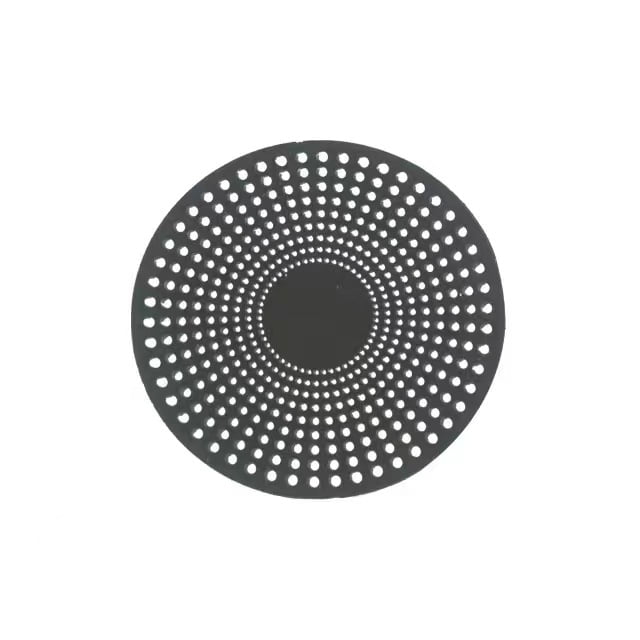

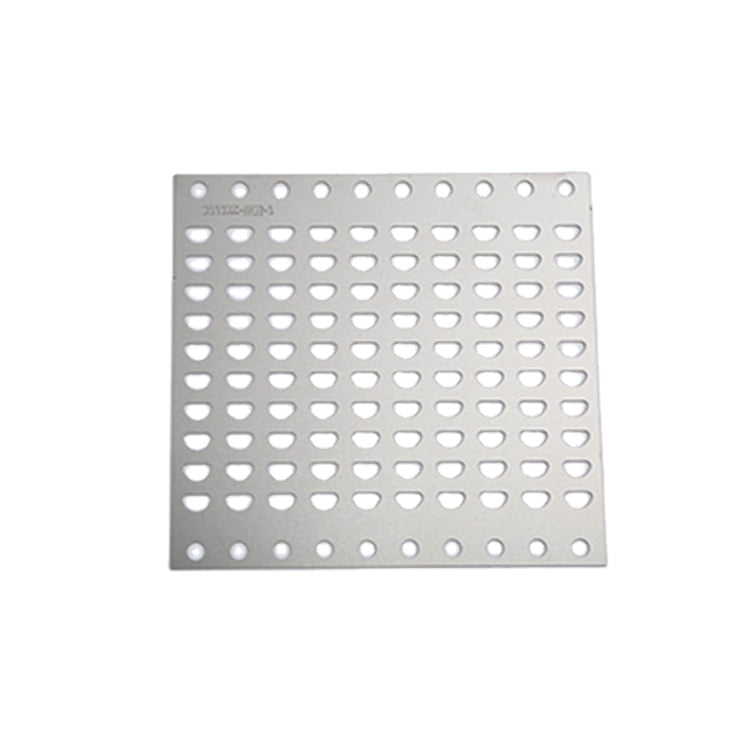

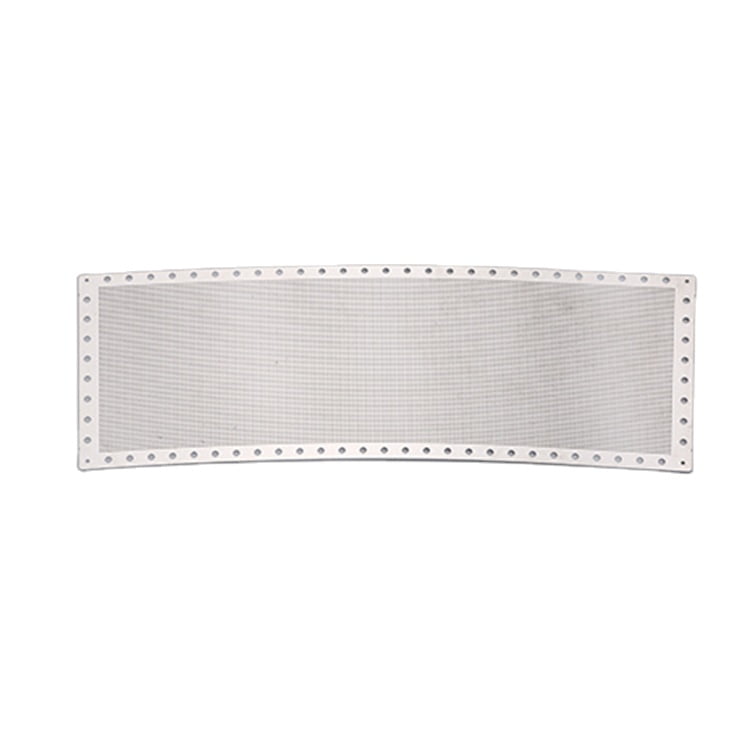

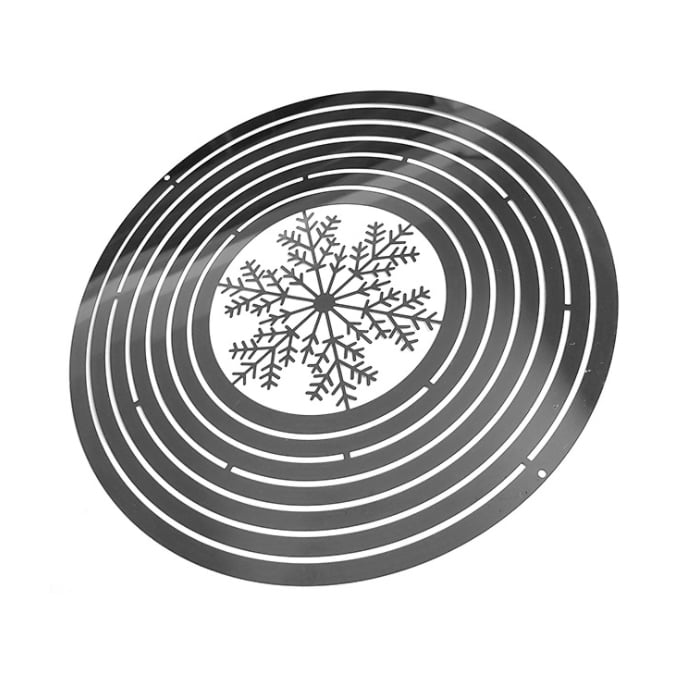

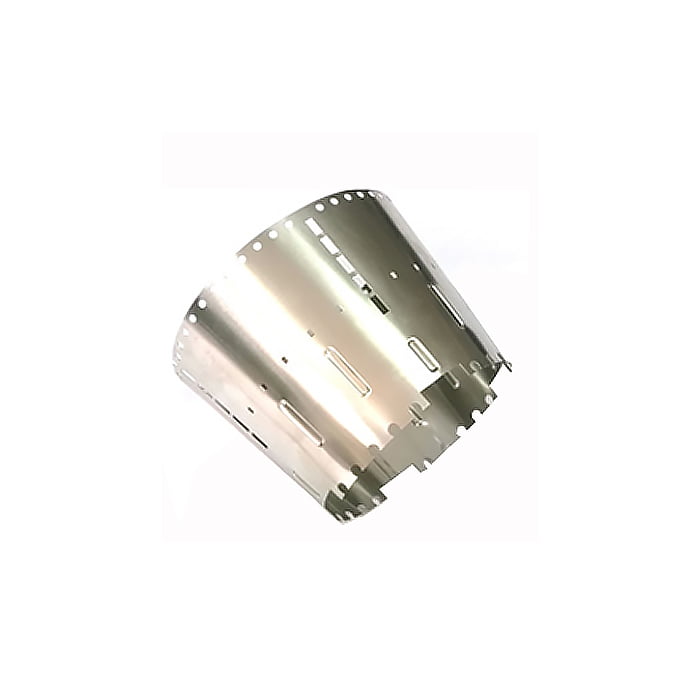

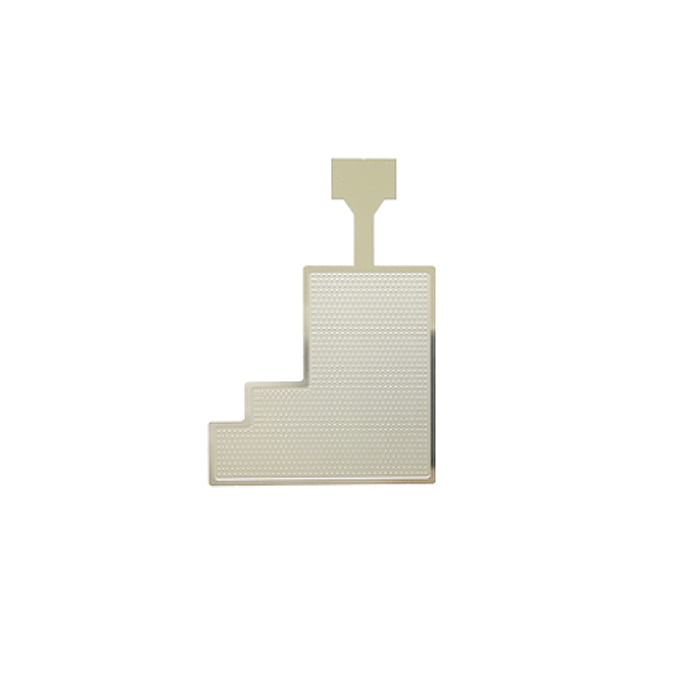

Metal Etching Samples

FAQ

Do you have your own factory?

Yes, our factory is located in Shenzhen, China. We own a very professional team.

How quickly can I get your response?

Within 24 hours.

Will you do 100% inspection before shipping out the orders?

Yes we do.

Can I have prototypes or samples before placing the order?

Samples are always available.

Are you experienced in different surface treatment?

Yes. We make surface treatment like: anodizing, nickel plating, electrolytic polishing, zinc plating, black oxide,TIN coating...

Are you experienced in different heat treatment?

Yes. We make heat treatment like: Nitriding, Quenching and tempering, Case Hardening, Carburize Hardening, Vacuum heat treatment

Do you make stock for your customers?

Yes in some cases we would make some stock for our customers.

Contact Us

If you need custom metal fabrication, please don’t hesitate to contact us immediately. We will provide you with the appropriate processing price within 2 days of receiving your material.