V&T Machining Masters Precision with Metal Chemical Etching for Steel:

In its unwavering commitment to precision and innovation, V&T Machining presents an optimized guide for metal chemical etching, focusing on the robust and versatile material, Steel. Renowned for its strength, durability, and wide-ranging applications, Steel demands a specialized approach for intricate pattern creation. With V&T Machining’s expertise, anticipate superior results in Steel metal chemical etching.

Unique Characteristics of Steel:

- Exceptional Strength: Steel is celebrated for its remarkable strength, making it a go-to material for applications where structural integrity is crucial.

- Durability: The durability of Steel ensures its longevity and resilience in diverse environments, from industrial settings to everyday products.

- Versatility: Steel’s versatility allows it to be adapted for various purposes, ranging from construction and machinery to consumer goods.

Metal Chemical Etching Guide for Steel:

| Steel Composition | Etchant | Etching Time (minutes) | Temperature (°C) | Mask Material | Mask Resolution (micrometers) |

|---|---|---|---|---|---|

| Steel | Ferric Chloride (FeCl3) Solution | 15 | 40 | Photoresist | 3 |

| Nitric Acid (HNO3) and Hydrochloric Acid (HCl) | 18 | 45 | Silicon Dioxide (SiO2) | 5 | |

| Solution | |||||

| Citric Acid and Nitric Acid Solution | 12 | 35 | Silicon Nitride (Si3N4) | 4 |

Analyzing Etchants for Steel Metal Chemical Etching:

Before delving into the specifics of metal chemical etching for Steel, it’s crucial to analyze the etchants chosen for the process. Each etchant brings unique advantages that contribute to the overall success of Steel metal chemical etching.

- Ferric Chloride (FeCl3) Solution:

- Advantages: Known for its controlled material removal capabilities, Ferric Chloride is effective for Steel chemical etching, allowing for precise pattern creation.

- Nitric Acid (HNO3) and Hydrochloric Acid (HCl) Solution:

- Advantages: Chosen for its fine balance between selectivity and efficiency, this solution provides controlled Steel chemical etching while maintaining the material’s unique properties.

- Citric Acid and Nitric Acid Solution:

- Advantages: This etchant combination offers controlled and precise Steel chemical etching, allowing for intricate pattern transfer. It is particularly advantageous for applications requiring high-resolution features.

Optimizing the Metal Chemical Etching Process for Steel:

V&T Machining adopts a meticulous approach to metal chemical etching Steel, ensuring superior results through the careful selection of multiple etchants. Ferric Chloride, Nitric Acid and Hydrochloric Acid, along with Citric Acid and Nitric Acid, combined with precise control of time and temperature, guarantee controlled material removal and pattern transfer.

Technical Precision and Expertise:

Our experienced team at V&T Machining leverages technical precision in metal chemical etching Steel projects. By fine-tuning etchant concentrations, temperature, and other critical parameters, we consistently achieve impeccable results, preserving the unique properties of Steel.

Benefits of Metal Chemical Etching for Steel:

- Precision in Pattern Transfer: V&T Machining’s metal chemical etching techniques offer unparalleled precision in transferring intricate patterns onto Steel surfaces.

- Enhanced Design Flexibility: Metal chemical etching allows for a high degree of design flexibility, enabling the creation of complex and detailed features on Steel.

- Application Versatility: The results of metal chemical etching make Steel suitable for a wide range of applications, including components for machinery, automotive parts, and consumer goods.

By choosing V&T Machining for your metal chemical etching needs on Steel, you’re partnering with experts dedicated to achieving precision, maintaining material integrity, and providing tailored solutions for your specific industry needs. Trust us to elevate your projects and exceed expectations in the dynamic fields of steel applications and beyond.

About Our chemical etching machine

Precision: The etching precision of our machine is 0.018mm, which allows us to manufacture micro-sized components with high accuracy.

Speed: The etching speed of our machine is determined by the quality and temperature of the etching solution used. Typically, higher temperatures result in faster etching.

Yield: Our machine achieves a high yield rate of 99.9% due to its high precision and controllable etching speed, which greatly improves manufacturing efficiency and reduces costs.

Our equipment comes from the Dragon Etching Chemical Etching Machine.

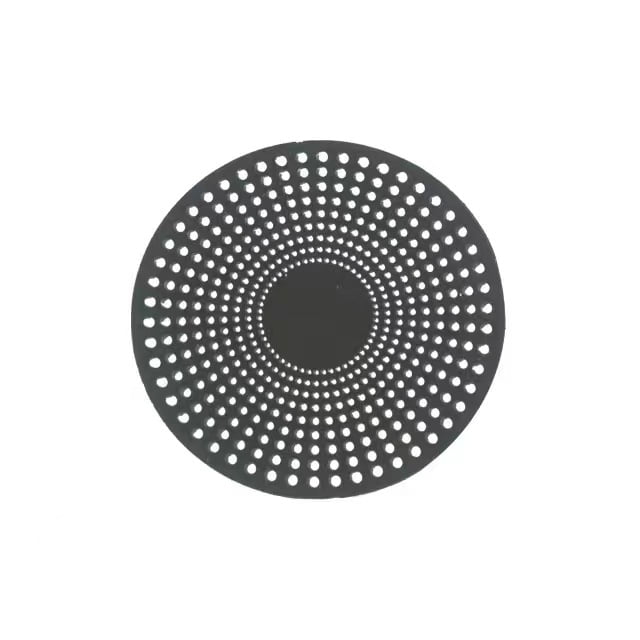

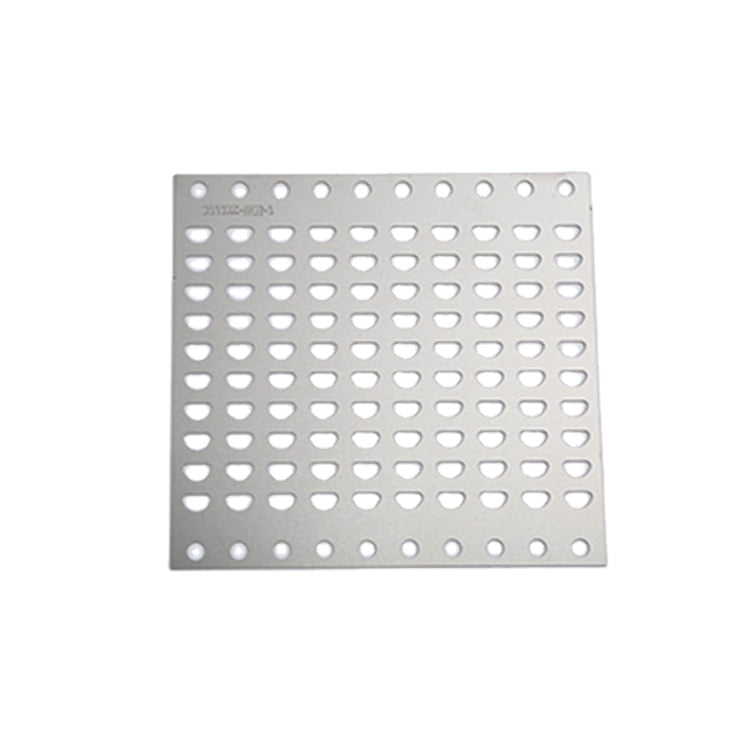

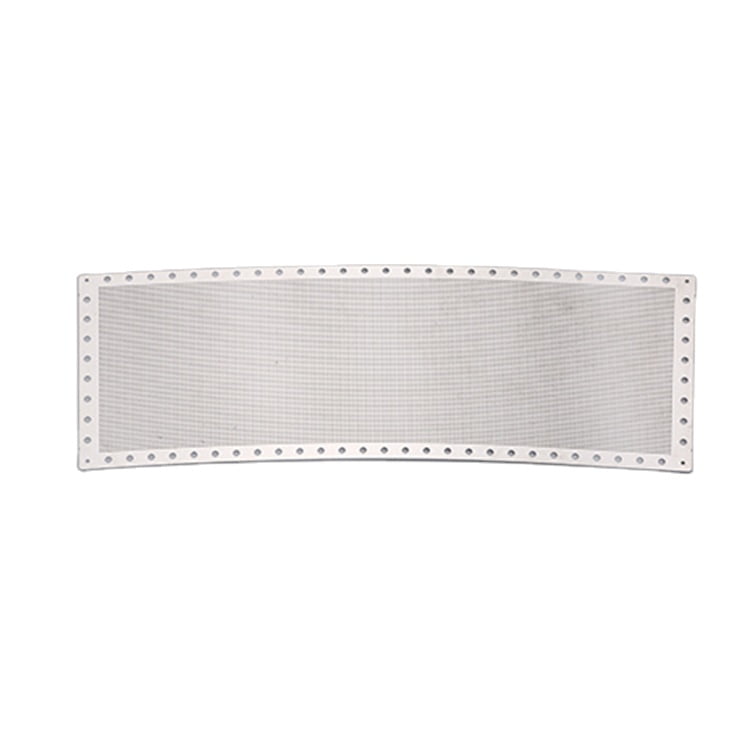

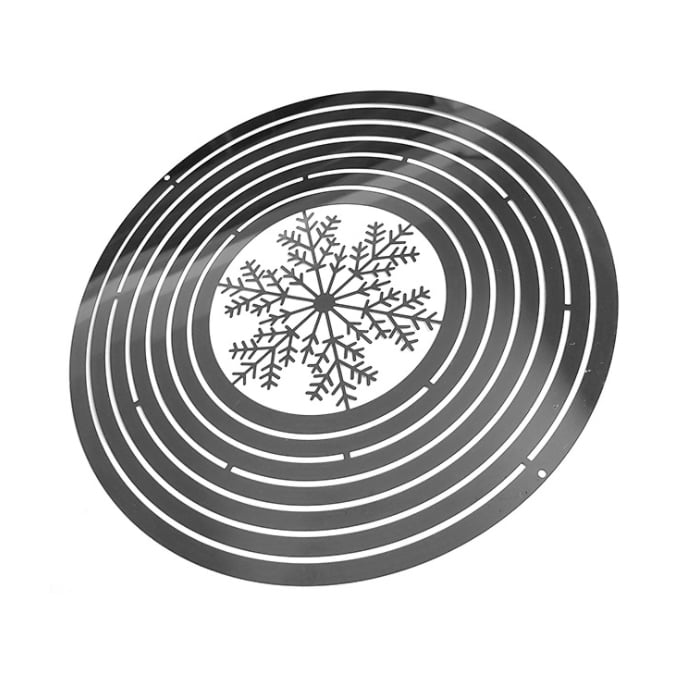

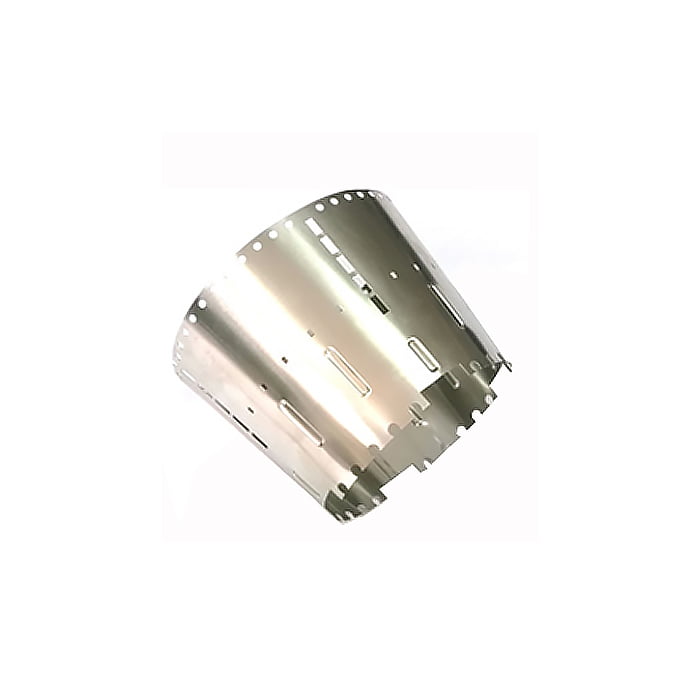

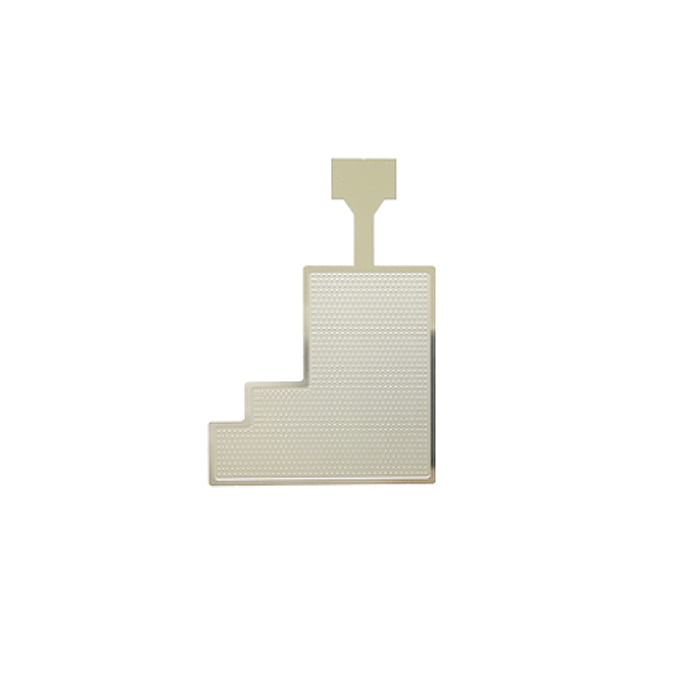

Chemical Etching Samples

FAQ

Do you have your own factory?

Yes, our factory is located in Shenzhen, China. We own a very professional team.

How quickly can I get your response?

Within 24 hours.

Will you do 100% inspection before shipping out the orders?

Yes we do.

Can I have prototypes or samples before placing the order?

Samples are always available.

Are you experienced in different surface treatment?

Yes. We make surface treatment like: anodizing, nickel plating, electrolytic polishing, zinc plating, black oxide,TIN coating...

Are you experienced in different heat treatment?

Yes. We make heat treatment like: Nitriding, Quenching and tempering, Case Hardening, Carburize Hardening, Vacuum heat treatment

Do you make stock for your customers?

Yes in some cases we would make some stock for our customers.

Contact Us

If you need custom metal fabrication, please don’t hesitate to contact us immediately. We will provide you with the appropriate processing price within 2 days of receiving your material.

View V&T service reviews

United Statesthis company is my go to! have used them multiple times great prices V&T is the best to work with!

Robert James

United Statesthis company is my go to! have used them multiple times great prices V&T is the best to work with!

Robert James

Quality yet cheap. Service Staff was very friendly and helpful. Measurements of parts was very accurate for the anodized aluminium, and prices were very competitive

Jerimiah D.

Quality yet cheap. Service Staff was very friendly and helpful. Measurements of parts was very accurate for the anodized aluminium, and prices were very competitive

Jerimiah D.

Good quality of the product, the color matches the photos. The milling machine operator is good. Thanks.

Francy J.

Good quality of the product, the color matches the photos. The milling machine operator is good. Thanks.

Francy J.

If you can deal with V&T you will have a very good experience. Sometimes they can be quite late though, and communication was bad for a while. I have dealt with this company for 3 years now. Mostly satisfied

Marianna B.

If you can deal with V&T you will have a very good experience. Sometimes they can be quite late though, and communication was bad for a while. I have dealt with this company for 3 years now. Mostly satisfied

Marianna B.